The Rebuild

A Defender Super Camper Built to Conquer the Globe

We converted our trusty Land Rover Defender double cab 130 into a bespoke camper. With our own hands!

(Please read before contacting us with questions!)

We loved our Howling Moon roof top tent - it was massive, the largest roof tent on the market in 2011 when we first installed it, and the 2.4m x 2.4m sleeping area was perfect accommodation for my wife, I and two young children. Fast forward to 2016 and, though we still loved the tent, we realised that it was time for a change if we were to continue travelling the planet in our Land Rover Defender 130. We had been living out of that tent permanently since we had shipped from South Africa to Uruguay in 2012, camping an average of 330 days of every year, cooking off the tailgate of the Landy and living outdoors.

_jp.jpg)

In 2015 we had driven up to Alaska and were returning south along the west coast when we were invited to a gathering of Defenders in the Alvord desert, Oregon. There we met Good Guy Steve, a tall, handsome, rock climbing Berkley professor who headed the paediatrics cancer research team. Yall should clone him. He had converted his Defender into a live in camper by grafting on a Marshall ambulance body from a Series 3 109. A sandstorm assaulted us after sunset and Steve’s camper was the only refuge from the melee, the insulated walls housed nine dusty people that evening and he later slept like a baby while the tented herd stuffed their ears with cotton wool and prayed for morning. Good Guy Steve gave us a tour of the rig once the dust settled and the sun rose. He had a single box bed which converted into a double bed, a small kitchen area, a fridge, a safe and low level storage. It was perfect for two people and with some modifications (specifically a pop top) could comfortably accommodate four. A seed had been planted. We had three options - sell the Landy on the black market in the USA for a pile of greenbacks then buy another Land Rover in South Africa and rebuild it, or we could convert our Defender. Breaking the law is not usually an option for us and we could not bear the thought of parting with the Landy. The third option was to continue travelling with the roof tent but we were seduced by the freedom and comfort of a camper. We knew that a build would not be cheap and we were on a first book sales budget, somehow we have to earn enough to not only build the camper but also ship it to Europe and travel to Asia.

Show More

We had worked hard on a Kickstarter campaign for our second book (Travel the Planet Overland) and had made the decision to invest the profits from the campaign in the build of a camper which could transport us around the world for at least the next decade, the cost of the camper would eventually be recouped as we would no longer have to rely on campsites and could work and live comfortably, thus becoming more productive.

It took almost a year of hard work, planning and design before I finally gave the project the green light. This was to be no ordinary camper - it had to be light and strong, able to go where Defender’s should while accommodating four adults comfortably. My son Keelan had grown to be a bull and the back seat of a Defender was designed for Hobbits not large boned Africans. The decision was made to remove everything from the front doors back and to build a pod with seating for the kids, to do this we would need to design the pod with a large walk through opening between the cab and the pod which would allow us to travel normally without locking the kids in a sealed box and we would be able to access the front seat while camping, important if we needed to escape hostility or potential threats while on some secluded beach. The walk through was an engineering challenge though, as we had to calculate the flex along the length of the chassis and design and build a partially suspended subframe, rigid yet flexible and we had to design a bulkhead which would mate the pod to the cab. A miscalculation could ultimately destroy the camper if the flexibility of the chassis under full articulation was not dissipated sufficiently through the subframe.

The interior would be modular (allowing for modifications as our needs demand, as the kids grow they will want to follow their own dreams) and lightweight, built on a frame of aluminum. We would have to work as we travel and needed a solar system which would be complimented by a dual battery with split charging system and a trickle charge option from shore power (I wrote our third book, Overlanding the Americas - La Lucha, sitting in the camper as snow fell on our campsite in Italy and I wrote this article while camping on a Black Sea beach in Turkey, the pod is our home and office). For the kitchen we sourced an outstanding fridge freezer unit from Snomaster (the 60 litre BD/C 60 Classic with low voltage cut off and a solar powered remote control), a dual gas burner stove complimented by a Coleman collapsible oven and a basin mated to 100 liters of house water. Each occupant also needed a full size bed to sleep in and the solution was to build a bunk bed within a security frame, the lower bunk formed by the joining of the two rear seats, and the top bunk available when the roof was lifted horizontally. A large storage box along the one wall would double as a bed and the back cushions would become a bed in the walkway. Jessica and Luisa would share a bed if we were unable to lift the roof while free camping in a city or questionable areas.

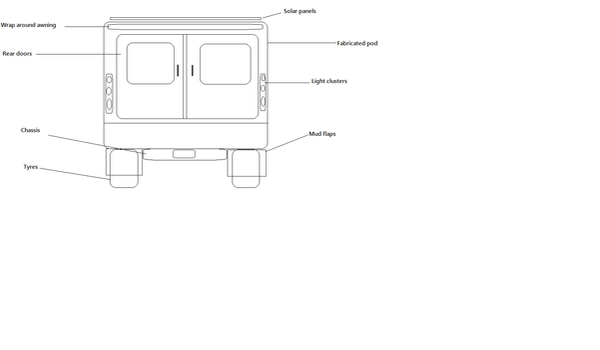

To increase the living space and reduce body roll we decided to have no storage cupboards above window height and we would install five large windows for maximum light and air flow. A large rear door would open horizontally and allow us to extend our living area to the outdoors. When camping in a city we could lock down the vehicle and sleep inside discretely and inconspicuously, but when we were on the beach or in the mountains we could pop the top, open all the windows and doors and have a panoramic view of our surroundings.

Blood, Sweat, Tears and Glory.

In December 2016 we stood in Southern Florida and watched as a new friend piloted a forklift and removed a large wooden box from the back of an eighteen wheeler. A German owned company, Total Composites, had agreed to supply us with the camper panels, windows, adhesives and sundry in exchange for exposure as they had just established a North American branch (they are ecstatic with the outcome as the rebuild video has had almost a million views on YouTube).

Time was of the essence though as the panels arrived a month behind schedule and Luisa had booked the flights from Boston to the United Kingdom and she had booked the shipping of the Landy from Miami to Southampton. We had 42 days to complete the entire build, about 142 days short of the time I needed.

Deconstructing our beloved Defender was heart breaking, she had faithfully transported us across three continents and we adored every inch of her. We began by removing the rear doors and seat box, then the roof and the rear tub, all of which were cleaned and prepared for a buyer Luisa had found on the internet ( the parts sold for $8000 which was $4000 less than the purchase price of the entire vehicle back in 2009. The sale of the parts covered almost half of the rebuild budget). We now had a bare chassis up to the B pillar and to achieve that we only had to cut the two two inch wide sills, Defenders really are the Mechano of the automotive world.

Our friend and host Ron, taught Keelan and I to weld while we were waiting for the panels to arrive from China and with the chassis exposed we could now begin manufacturing the subframe. The work area was not a fully equipped workshop but it had a level concrete floor and a plastic covered frame and Ron had any tool we might need. A large industrial fan helped us to stay cool through the heat of a Floridian winter and a Yeti cooler full of ice kept us refreshed during the 15 hour work days, NPR or one of the local stations on the radio. At the end of the day me and my new friend Pepper, who had bitten me when we first met, sat and shared a few beers as the sun set, planning the next days work. In bed by ten exhausted and up at five, working as the sun rose over the orange plantations. Luisa would work night and day, sourcing materials and parts while designing the horizontally lifting roof and water and electrical layout and taking care of all logistics and book sales. Keelan was my back, doing the heavy lifting and the maths and helping with the on the spot decisions, designs and fabrication.

Shayne, an Australian whose red 130 had been proclaimed by Outside magazine to be the best overland Defender, offered his help and advice and found himself wiring the camper. He also offered eight boxes of nuts and bolts, a few boxes of odds and sods and tools which he used to build his own vehicles and which he offered to us to use as we needed. Ah, the simple pure pleasure of a metric measuring tape. And Jesus, the general manager of Ron’s business, was always there when we needed a tool or an extra hand or a good idea. Often Jesus would force us to stop working to join his family for a cold Modelo and a few plates of delicious food.

We used 1”x 2” steel for the subframe, 2”x2” would be very heavy and too rigid, allowing no flex at all. Keelan and I cut the steel to lengths and began to weld on top of a large metal table in one of Ron’s massive greenhouses, sweat dripping down our backs. With the frame welded and structural gussets added for extra strength we took an angle grinder to the uglier welds, scrubbed the frame with a metal brush and painted the clean frame with four coats of rust inhibitive primer and four coats of rust inhibitive top coat, gloss black. We used the same steel to weld a safety cage which would surround the rear seating and provide a base for a bunk bed and the two inward facing rear seats.

The bulkhead which mated the pod to cab came next. I had stumbled across a German build on the internet while researching build options a year earlier. Mario had built a pod very similar to what ours became but there were a a few significant differences; our roof is a horizontal pop up, we have a large rear door and large windows while he has a small side door and relatively small windows and he welded an aluminum frame for the walls of his camper while we used panels joined with extrusions. I learned two things from Mario; first that you can build an overland camper in your driveway and secondly he had devised a way to connect the pod to the cab using brackets and a mating surface made of marine ply. He also very kindly provided detailed photographs and advice when I asked for clarification - Waltzing Matilda, you are the man.

Another source of information was Jose Luis from Urocamper, a man who had his hands full building excellent campers all day long and STILL took the time to reach out and offer advice! We communicated mostly through hastily drawn layouts and ideas. At the time of Covid 19 in Spain he closed his camper works and turned all energy and efforts to manufacturing face masks for health workers. Jose Luis is a dude. If you ever chat to him tell him we say hi!

A huge thank you to our friend Ulrich Dolde who was in the process of publishing his excellent camper build bible as we started our build. He very kindly sent us a PDF of the book to help us out. The book is an excellent source of information and we highly recommend that you invest in a copy if you are planning your own build.

I started working on the cab/pod coupling template a day after we installed the new roof which was an old Defender roof which Ron had lying in the yard and kindly donated to our cause. The roof was cut with a jigsaw and installed, and using a large piece of plywood from the Total Composites shipping crate we made a template which was meticulously cut and sanded until it fit perfectly inside the arch of the roof and into the one centimetre depression in the B pillar. Once the template was perfect we then cut the final mating piece of marine plywood which was planed and sanded until it too fit perfectly. With the subframe and mating piece in place we were then able to finish the subframe floor and begin mounting the panels. We fabricated wheel arches and restored our old jerry cans and roof rack and measured the composite panels five times and cut once (note, Total Composites are able to cut the panels you require to your exact requirements).

With D Day approaching rapidly we realised that we would not be able to complete the interior, well, Keelan and I realised this but Luisa insisted that she could complete the interior in one week. We begged her not too try and to rather help us finish the structure, it had to be roadworthy so that we could drive it 70 miles to the shipping agent. Luisa then spent the next week walking in circles, stealing the tools we were using and moving pieces of wood around, she was waiting on the delivery of parts to be able to finish the roof which she completed the day before we were to head to the shipping agent.

With the clock ticking we resprayed the front of the Defender, including the new roof, and with the help of Ron, Shayne and Jesus we installed the roof and Luisa packed our belongings into the Landy while I finished the fabrication of the rear door. Without the luxury of a test drive we drove the Defender out onto the agricultural roads and, confident that the pod was not going to fly away, drove rapidly to the port, our hearts in our throats. The camper drove beautifully and we made it to the shipping agent with only a minute to spare, safely parked in a warehouse surrounded by Italian supercars we took one last photo before walking away. The next day we would take a train from Florida to Washington DC and would be able to relax for the first time in months.

In March 2017 the Land Rover arrived in the United Kingdom and we completed the interior, electrical systems, roof and storage boxes. We then drove her down through central Europe to Portugal and then started across to Turkey. In sublime Northern Spain we chartered an offroad course through the Pyrenees to Andorra where we would enter the tiny mountain state through the Smugglers Route. In the mountains we were to test the campers off road ability and our construction, nervously achieving full articulation as we followed mountain trails known by few. The camper performed excellently, showing no signs of structural stress or fatigue. The subframe construction and suspension system dissipated the flex of the chassis and the cab/pod coupling remained rigid. We have since driven highways, byways, mud, beaches and mountains and the Defender has performed excellently; the dimensions of the camper are perfect, compact enough to explore small Italian villages and tight trails but large enough to offer a comfortable home for the four of us. We did find the ride quite bouncy and installed a set of rear Air Lift air bags which canceled the low speed body roll and second bounce on speed bumps. Further modifications have included an extended roof rack, sand ladders/ side table from Entreq, a Howling Moon 3000 awning with walls, a Quick Pitch Shower Cubicle, Bearmach rock sliders and led spotlights, a new gearbox, an 11kg LPG gas tank for cooking, . When the faithful TD5 eventually succumbs to many hundreds of thousands of miles we will invest in a Cummins 2.8 turbo diesel.

Parked next to the Atlantic in South Africa I sipped a cold drink and gazed passed my sandy feet to my family swimming. Smoke rose from the barbecue and a breeze blew through the camper. Through blood, sweat and tears (and about $20 000 of cold, hard cash) we had made our dream come true. I think we deserve a cold beer and a lazy swim. Especially after a 8 month drive across West Africa where the camper performed faultlessly (but the Landy had some mechanical and electrical issues).

-3_edited.jpg)

Show Less

YouTube Videos Featuring the Rebuild

These videos greatly help explaining and shedding light on the reasoning and process of our camper conversion. The one featured to the right is our most popular video of the rebuild with over 830K views that features the rebuild start to finish. The other two featured here show how to choose the right vehicle for you and how we upgraded the suspension of the Landy.

Land Rover Defender 130 Camper Conversion: 16:44, 835k views

Choosing Your Overlanding Vehicle 17:39, 10K views

Airbag Installation: 6:11, 10K views

Index

Click on any of these to be taken to that section of the rebuild.

Introduction

After travelling Argentina to Alaska and having to experience everything from the blistering hot temperatures of The Atacama Desert to the freezing nights in Patagonia totally exposed and un-sheltered from the elements. Rooftop tents are great but we needed to make a live in situation sheltered from the elements that would not reduce our offroad abilities and be small enough to fit within a Hi-cube container. After roughly a year of planning and exploring our options we decide to build our own Box onto the rear of the landy that would let us freely pass trough from the cab to the box.

The Landy Loses some weight!

The Beauty of the Land Rover Defender 130 is the Possibility to disassemble the vehicle completely like Adult Lego, we started with removing the Rooftop Tent and rear Canopy. From that point we removed the rear doors and rear bench to give us easy access to the roof of the cab, after removing all connections between the roof and mounting points we lifted and removed it. Then we started dismantling the rear Tub. We removed all bolts mounting it to the Chassis and disconnected all cables and tubes on the tub then used a forklift to carefully lift the rear tub up making sure no cables were getting snagged or caught and slowly lifting it off till it was fully removed. The Cab off the vehicle is actually split in to multiple parts so all you need to do is remove the rear section of the cab which is essentially everything behind the Centre Support beam.

Design

We were sure not to remove anything from the landy until the panels arrived from Total Composites at that point we loosely built the box in the workshop and checked all dimensions before deconstructing the box and leaving it off to the side while we dismantled the landy. The Design of the rear box was a long process that we had been planing for over a year,everything from how tall the box was going to be to how the box would mate to the Cab and Chassis of the 130 were debate and discussed down to the finest details.

Peparing Cab for Mating

After Dismantling the rear of the landy until the center support beam, we determined that cutting the Cabs roof down inline with the Center support beam would be best for mating Cab to the rear box. Using scrap pieces of wood from the containers the panels arrived in, we sketched and cut them down to fit the internal dimensions of the rear half of the cab. We used the lip Behind the Beam that is originally designed to hold the rear doors flush when closed as the borderline for our cab and constructed a frame the increased both the strength and surface area at the rear of the vehicle so we could mate the box to the cab

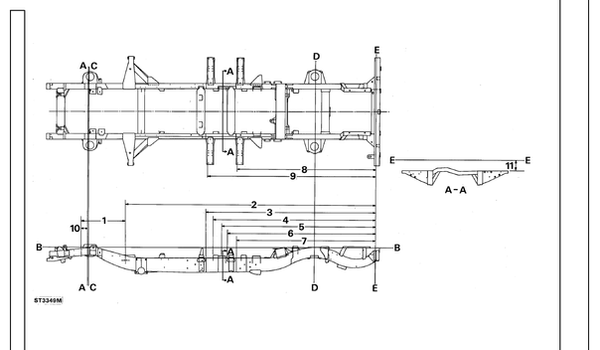

SubFrame

We used 1”x 2” steel for the subframe, 2”x2” would be very heavy and too rigid, allowing no flex at all. We cut the steel to lengths and began to weld on top of a large metal table. With the frame welded and structural gussets added for extra strength we took an angle grinder to the uglier welds, scrubbed the frame with a metal brush and painted the clean frame with four coats of rust inhibitive primer and four coats of rust inhibitive top coat, gloss black. After that we mounted a strong layer of wood to the Subframe that acted as mating surface between the Subframe and the Floor panel. That additionally protected the semi-fragile floor panel from cracking and being exposed to the elements.

Floor & body

The subframe wood and the floor were both measured and cut to provide easy access to the fuel pump as trying to replace the fuel pump in a stock 130 is already difficult enough whereas with the Subframe in place it would be Impossible to replace it. We used Sikaflex to glue all of the panels and the 90° angle extrusions except for the rear where we had to use bent steel plate to secure the angled lower plate. The Walls each have two decently large windows that gives the box enough natural light that we feel like we're inside and outside at the same time. The Rear door was made last minute as our schedule and deadline were nearing mercilessly. We needed to have the landy in the Shipping yard before the end of our last day, as Luisa and Keelan packed everything into the rear box as quickly as they could Graeme was finishing the latching systems on the rear door.

Roof

We built the roof in the nick of time along with the rear door as time was running out to get the Landy on a ship to Europe, we designed the roof to fit over the body by intentionally making the roof slightly larger. After arriving in Europe we planned to make the roof lift a extra meter but after seeing firstly how it was nearly too tall for us to touch and secondly how high-speed winds would most likely turn our roof into a oversize kite, we decided that the extra height wasn't that important. The reason we planned to raise the roof that high was so that Full sized Keelan could sit upright in the top bunk.

Interior

We Built the Interior in a fully modular fashion so at anytime we could remove everything in the box easily and fairly quickly. We used aluminium square tubing and Connect-its to create the shell of the cabinets and benches without welding or any nuts and bolts. After the shells were made we fastened wood onto the exterior facing parts of the shells. In the Kitchen area we used steel right angle profiles to let the draws rest on so they could easily be removed or repaired since there are no complex rail systems being used like we had done with the rear draw system since 2010. At first when we built in the United Kingdom the Drawers didn't have any sort of latches or locks which proved to be no problem on the English highways but when going offroading we had a rude awakening as the kids had to jump out of their seats while being thrashed around to stop all our cutlery and glasses from flying straight out from the railing. The bed on the left side of the box also acts as our main storage area, being the home of all Clothing, Technology, and other assorted chaos.

*The Interior is currently being renovated!

Life After the Rebuild

On a day to day basis the comfort, convenience, safety, and adaptability of the rebuild make it worth it. We can safely travel anywhere regardless if there's a massive heatwave or chilling thunderstorm we know that we'll be okay. We often compare the Rooftop setup to the rebuild and in almost every situation we're happy that we did the rebuild, sometimes we wish we had done it sooner!

Frequently asked questions

These are the most common questions about the build. It's easier to answer each one here then in Private FB/IG messages.

Q: How much does it weigh?

A: 3 tons. We aren't entirely sure because every Weigh Station we've been to has given us vastly different results

Q: How much did the build cost?

A: Roughly 20,000 USD

Q: What are the dimensions?

A: The dimensions of the box are L: 3.3m W: 2m H: 1.6m

Q: Do you experience body roll?

A: We would experience body roll at low speeds while off-road. When we arrived in Europe we installed airbags in the rear suspension and that significantly reduced body roll while driving in all conditions

Q: Where did you source the materials?

A: The Panels came from a company called "Total Composites" and the rest of the materials were sourced from multiple online stores

Q: How did you make the roof?

A: The roof was made to be slightly larger than the body so that it could be slotted over the box. Doing it this way made it waterproof and more secure when closed

Q: What would you have done differently?

A: All things considered the main things that we would have changed about the build aren't actually the build itself but tools and time restraint we had. If we were to do it over we would make sure we have a full workshop of tools and more time. Our Composite panels were late to arrive and that threw all of our timings out. We ended up having to put the Defender in a shipping container without even having a test drive

Q: Where do the children sit/sleep?

A: We made inward-facing seats behind the front seats that are secured inside a steel security cage that doubles as a bunk bed platform. The inward-facing benches fold down to make a bed that Keelan sleeps on. When the roof is lifted there is a bed on top of the security frame that Jessica sleeps in. In situations where we can't lift the roof, Keelan's bed is wide enough that Luisa and Jessica sleep there and Keelan sleeps on Luisa's bed.

Q: Did you modify the suspension?

A: Yes, we installed Heavy Duty springs from BearMach and custom shocks from Cibex

Q: What is the fuel consumption?

A: It depends on a couple factors, but mostly it depends on which way the wind blows! We get an average of 8.5km/L

Q: Did you make any changes to the engine?

A: The only notable change we made was installing a Little Black Box which you can find a review of here. Although that was installed when we first purchased the vehicle!

Q: What spares do you carry?

A: We carry a wide range of spares

Q: Does it fit in a shipping container

A: Yes! We specifically designed it to enter a 40ft Hi-Cube shipping container